Recap SB 72-2208 AD 2016-18-17 2nd Stage Impeller

AD 2016-18-17 applies to the second stage impeller part number 893482-1 through –5 inclusive or 3107056-1 or –2 installed. The AD was prompted by the discovery of cracks in a 2nd stage impeller during a routine shop visit. The AD was issued to prevent failure of the compressor impeller, uncontained parts release, damage to the engine and damage to the aircraft.

Compliance with the AD is required at first removal of the second impeller or within 11,500 cycles of the effective date of this AD which is November 4, 2016. Honeywell SB 72-2208 describes procedures for replacing the above listed 2nd stage impellers. Second stage impellers 893482-1 through –5 and 3107056-1 and –2 may be replaced with New 3108387-1 impeller which are life limited to 30,000 cycles. Second stage impellers 893482-1 through –5 and 3107056-1 and –2 may be inspected and upon passing inspection be reworked to part numbers 3107167-1 though –5 with a life limit of 10,500 cycles. The rework option may represent a significant cost saving to operators however if the impellers fail the inspection they will still require replacement at additional cost to the operator. This inspection and rework must be accomplished Note: 3108387-1 and 3107167-1 though –5 2nd stage impellers are life-limited and require a Life Limit Part Log Card to be maintained. Refer to TPE/TSE331-72-0019, TPE331-72-0117 or TPE331-72-0180 as applicable for life limit instructions.

Meet: Keith Guffey

Work Order Admin

Keith Guffey began his career with CD Aviation Services in 2005. He is the Work Order Administrator. His tasks include opening the customer work orders, monitoring customer costs, generating shop quotes, final customer costs and invoicing. Keith is also the chief analytics professional providing administration with pertinent financial data. Keith’s keen eye for detail and his knowledge of the engines make him an invaluable member of the CD Aviation Ser-vices team.

Keith Lives in rural Neosho with his wife and in his spare time is a master craftsman working with stone and wood. He is an out-doorsman and enjoys motorcycle riding in his leisure time.

Did you know

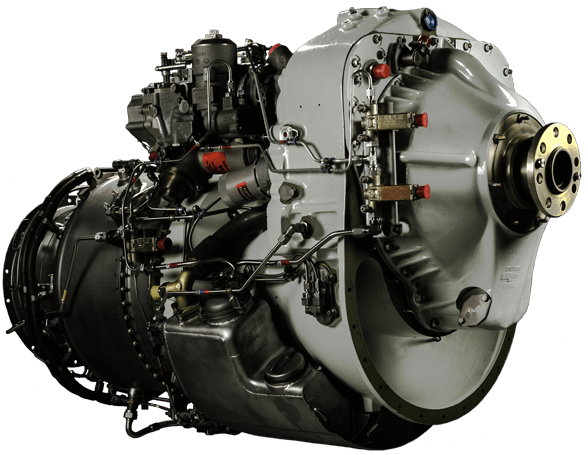

Fixed Shaft Design (TPE331)

The fixed shaft engine design has lower specific fuel consumption making it a more fuel efficient design. This significantly reduces the hourly fuel cost of operation.

The ability to provide power rapidly (without a spool up time – delay) is a significant safety advantage if the pilot gets a little behind the power curve.

The overhaul cost on the TPE are significantly below the cost of the PT6.

The ram air inlet and the straight thru exhaust enhance engine and aircraft in-flight performance versus the free turbine configuration.

Here’s a Tip!

When a TPE331-5, TPE331-6, TPE331-10 or TPE331-11 come due for Hot Section Inspection it is a good idea to do a compressor refurbishment to insure your engine makes OEM rated power. With a compressor refurb you know you are maximizing your engine’s power potential and this will give you the opportunity to comply with AD 2016-18-17 and SB 72-2208.

CD Aviation Services has complete Prop Stand testing capabilities for all models of the TPE331-1 through -12 series engines. CD prefers the use of the prop stand over a dyno in that the prop stand provides the ability to functionally test the prop governing system as if the engine was installed in the aircraft. The dyno uses a load bank attached to the prop shaft and cannot functionally simulate the prop governor system.

Prop stand tests can include:

- Recompensation test which establishes OEM certification back to standard day requirements for engine shaft horsepower. This is required any time a compressor Impeller is replaced or the engine has to be shimmed after compressor refurbishment.

- Lebow torque calibration sets up the engine torque indication for the aircraft.

- Vibration surveys to ensure engine vibration limits are within specification.

- Troubleshoot engines for low performance prior to maintenance.

- Set up all the rigging parameters to minimize setup on the aircraft.

Services Offered for your TPE331

- Scheduled and Unscheduled Maintenance Engine Removal and Reinstallation

- LRU Trouble Shooting and Replacement Field Service

- Engine Evaluation Log Book Reviews

- Engine Overhaul CAM Inspections Hot Section Inspections

- Gearbox and Compressor Inspection Repair Vibration Analysis Prop Balance

- Borescope Inspections 24-Hour AOG and Technical Support

What’s Going down i am new to this, I stumbled upon this I have found

It absolutely helpful and it has aided me out loads.

I hope to contribute & aid other customers like its helped me.

Great job.