Sometimes, an operator’s only indications of impending problems are when a disaster occurs perhaps even in mid-flight. However, this is rare. More often than not, there are indications for before complete system failures occur that had they been heeded could have averted disaster. And when it comes to a craft’s auxiliary power unit (APU) – which provides electrical power and the pneumatic supply for both air conditioning and main engine start – the impact of a malfunctioning unit can be significant. Thus, aircraft APU maintenance and preventive maintenance should never be ignored. These 3 best preventive maintenance tips will help ensure your APU functions smoothly.

Connector care: Is the craft you are maintaining experiencing intermittent or lost electric signals that are leading to auto-shutdown and/or difficulty in starting? This could be the result of a connector problem. You should always make sure to clean your connectors as this improves their conductivity. Moreover, as a preventive maintenance procedure, you may wish to do this every time you remove the connector. Ultimately, this will prevent more serious maintenance interventions and expensive parts replacements.

Conduct periodic monitoring and inspections: As we said before, major problems with a plane’s APU don’t often just spring up with any warning. You can keep on top of things by doing continuous on-condition monitoring of APU parameters. This will allow you to detect anomalous variations in performance and to address them at an early stage. This can potentially save you manpower hours and money. Specific conditions that may be signs of a problem include oil leaks, the unexplained presence of debris, etc.

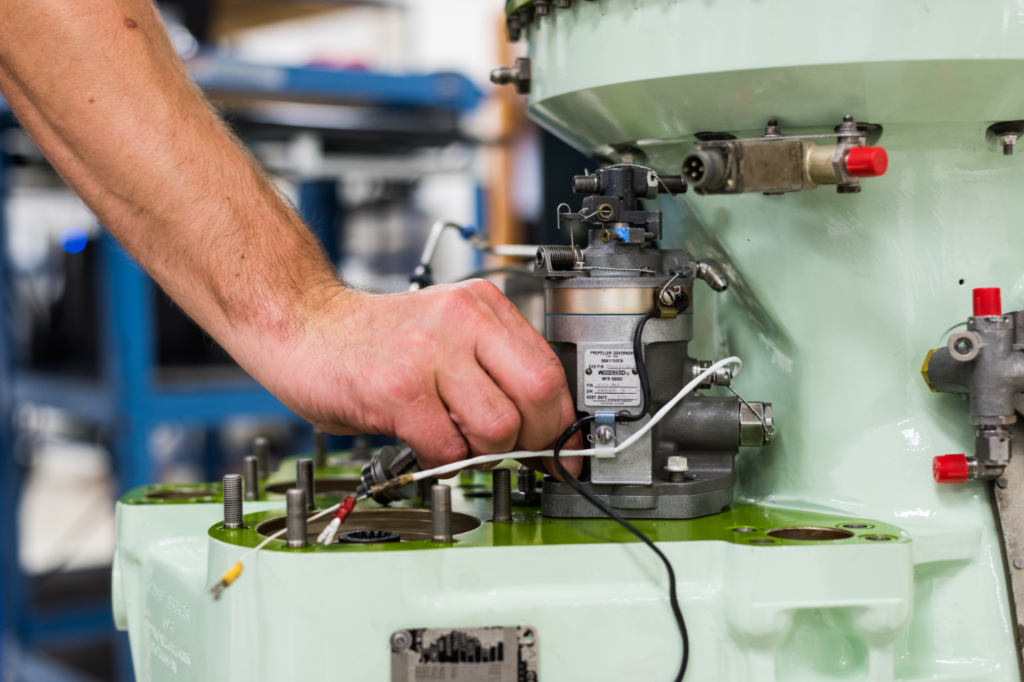

Replace parts as soon as possible: If you detect issues such as a damaged sensor connection or fuel manifold, have the issue addressed immediately. Moreover, replace APU parts well before the end of their expected life cycle. Start by inspecting and replacing starters, fuel pumps, and any other device that may develop into more issues if it is allowed to go on unaddressed.

There is an old saying that the best time to repair a roof is before it starts to rain. You should always endeavor to head off minor problems before they become major ones. That is what preventive maintenance is all about. CD Aviation provides TPE331 service and we are a repair station for the TFE731 and GTCP36 series engines as well.