One of the most cost-effective and non-destructive methods of gauging the condition of an aircraft’s engine is to use the standards and guidelines of a Spectrometric Oil Analysis Program (SOAP). As you know, by testing the chemical composition of metal particles which may be suspended in an airplane’s oil samples, engineers are able to identify when an engine should be serviced and whether or not there has been abnormal wear and tear on certain parts. Some argue that this method may even be of help in heading off catastrophic engine failure down the line. It is therefore only natural to wonder how much information can be obtained using SOAPs.

What Oil Analysis Can Tell Us

The Honeywell SOAP consists of a two part analysis. First, the spectrometric analysis determines, in parts per million (PPM), the suspended metal particle content in the lubrication system of an engine. Secondly, filter analysis is the most effective means of identifying problems in the engine lubricating system. The filter analysis will reveal coarse or more rapid wear of internal engine parts which will result in the production of large metallic particles which become trapped in the oil filter.

From the amount and type of metal found by the filter analysis, the condition of engine parts contacted by the engine lubricating oil can be monitored and impending failures of specific parts are predictable with a high degree of certainty. It should be noted, however, that this analysis involves subjective interpretation of the filter sample analysis data compared to historical analysis data for that particular engine. Mechanical failures cannot always be foreseen from analysis results nor is the program able to predict the possibility of sudden mechanical failures due to oil starvation, part failures or foreign particle introduction into the oil system.

The Goal of SOAPs

* Prevention of catastrophic failure

* Prevention unscheduled downtime –

* Prolonging of machine

* Increased efficiency of parts that are in use

There are three different conclusions that are derived from SOAP / Filter analysis:

1) The engine wear trend is normal.

2) The engine wear should be closely monitored by sampling at the routine hour interval.

3) If the engine wear indicates that an inspection of the engine is required.

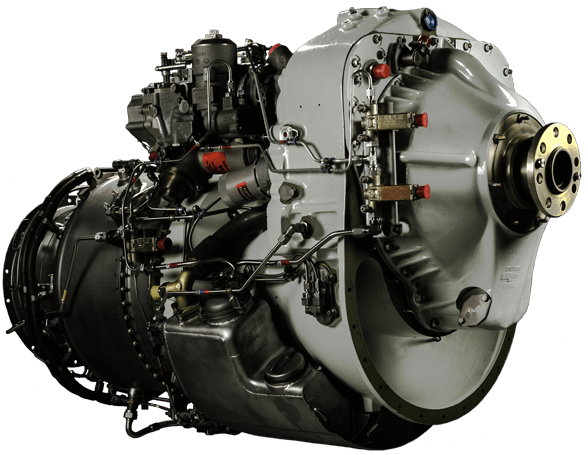

In conclusion, SOAPs are a supplement to a full and thorough check of an aircraft’s engine. Particle counting appears to be a promising method of supplemental analysis from the standpoint of failure prevention but it can never completely replace the diligence and competence of a repair and maintenance crew. CD Aviation Services provides TPE331, TFE731, and 36-100/ 36-150 APU maintenance and service.