Service Bulletin of the Quarter SB 72-2190 Applicable to the TPE331

This is a Category 2 Service Bulletin: Problem: Some PPC assemblies, PN 869130-11 thru -14, -16 thru -19, -30 and PN 895481-1, -2, -4 thru -7, -17 thru -20, -22, do not have an internally-threaded hole in the splined end of the shouldered shaft, PN 865567-2 and PN 895472-2. Background: The threaded hole in the splined end of the shouldered shaft can be used to accommodate a secondary retention feature for the aircraft control linkage interface. The secondary retention feature is supplied by the aircraft. This service bulletin gives instructions to rework the PPC assemblies, PN 869130-11 thru -14, -16 thru -19, -30 and PN 895481-1, -2, -4 thru -7, -17 thru -20, -22, to incorporate a threaded hole in the splined end of the shouldered shaft, PN 865567-2 and PN 895472-2, as applicable. This service bulletin also gives authorization to install PPC assemblies, PN 70000295-11 thru -14, -16 thru -19, -30 or PN 70000298-1, -2, -4 thru -7, -17 thru -20, -22, as applicable, that have been identified as having a shouldered shaft with the threaded hole.

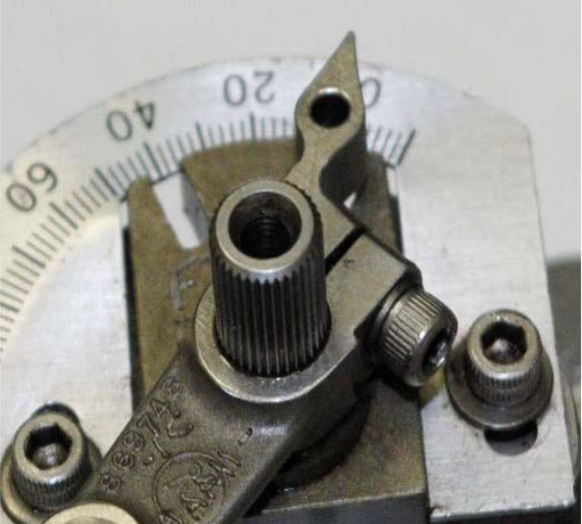

Example of the Threaded Hole in the Splined End of the Shouldered Shaft

AD 2017-07-01

AD 2017-07-01 issued effective date May 5, 2017

SUMMARY: We are adopting a new airworthiness directive (AD) for certain M7 Aerospace LLC Models SA226-T, SA226-AT, SA226-T(B), SA226-TC, SA227-AC (C-26A), SA227-AT, SA227-BC (C-26A), SA227-CC, SA227-DC (C-26B), and SA227-TT airplanes. This AD was prompted by a detachment of the power lever linkage to the TPE331 engine propeller pitch control. We are issuing this AD to prevent detachment of the power lever linkage to the TPE331 engine PPC, which could result in an uncommanded change to the engine power settings with consequent loss of control.

This AD requires repetitively inspecting the propeller pitch control for proper torque, with corrections as necessary until required replacement or rework of the PPC assembly to have a threaded hole in the splined end of the shouldered shaft and installation of a secondary retention device is done.

We are issuing this AD to correct the unsafe condition of these products.

(1) Within 100 hours time-in-service (TIS) after May 5, 2017 (the effective date of this AD) and repetitively thereafter at intervals not to exceed 100 hours TIS, visually inspect the PPC lever to assure the attachment is properly installed following the applicable service information listed in paragraph (h)(1)(i), (ii), or (iii) of this AD, as applicable.

(i) For Models SA226 Series: M7 Aerospace SA226 Series Maintenance Manual Temporary Revision 71-02, dated March 15, 2016.

(ii) For Models SA227 Series: M7 Aerospace SA227 Series Maintenance Manual Temporary Revision 71-03, dated March 15, 2016.

(iii) For Models SA227 Series Commuter Category: M7 Aerospace SA227 Series Commuter Category Maintenance Manual Temporary Revision 71-02, dated March 15, 2016.

(2) The rework/replacement required by paragraph (i) of the AD and the installation of the secondary retention device required in paragraph (j) of this AD terminates the repetitive visual inspections of the PPC lever attachment required by paragraph (h)(1) of this AD.

Within the next 600 hours TIS after May 5, 2017 (the effective date of this AD) or within the next 12 months after May 5, 2017 (the effective date of this AD), whichever occurs first, do the actions in either paragraph (i)(1) or (2) of this AD following the Accomplishment Instructions in Honeywell International Inc. Service Bulletin TPE331-72-2190, dated December 21, 2011, as referenced in the applicable service information listed in paragraph (g)(1), (2), or (3) this AD.

Meet: Kim Smith – Operations Manager/Parts Purchasing Repair Administrator

Kim Smith is the Operations Manager / Parts Purchasing and Repair Administrator for CD Aviation Services. Kim began her aviation career with TECI as an inventory specialist in August of 2001 and made the move to CD Aviation in December of 2007. Kim is responsible for the constant flow of inventory purchasing and repair in and out of CD Aviation including oversight of shipping and receiving. She spends many hours including some evenings and weekends to ensure that CD Aviation meets critical customer deadlines for engine maintenance turn time.

In her spare time, Kim enjoys spending time with family at her home in Joplin, MO. Kim is a dedicated team player and is vital to the success of CD Aviation Services.

Services Offered for your TPE331

- Scheduled and Unscheduled Maintenance

- Engine Removal and Reinstallation

- LRU Trouble Shooting and Replacement

- Field Service

- Engine Evaluation

- Log Book Reviews

- Engine Overhaul CAM Inspections

- Hot Section Inspections

- Gearbox and Compressor Inspection Repair

- Vibration Analysis Prop Balance

- Borescope Inspections

- 24-Hour AOG and Technical Support

Call Us anytime 417-206-2327 www.cdaviationservices.com