Airworthiness Directive of the Quarter 2018-13-05

This AD applies to Honeywell TPE331-1, -2, -2UA, -3U, -3UW, -5, -5B, -6, -6A, -8, -10, -10AV, -10N, -10P, -10R, -10T, -10U, -10UA, -10UF, -10UR turboprop and TSE331-3U turboshaft engines with hydraulic torque sensor gear assemblies, part numbers 3101726-1, -2 or-3 installed.

This AD was prompted by recent reports of failures of the direct drive fuel control gears and bearings in the hydraulic torque sensor gear assembly, P/N 3101726-3. This AD was issued to prevent failure of the hydraulic torque sensor gear assembly. The unsafe condition, if not addressed, could result in failure of the hydraulic torque sensor gear assembly, in-flight shutdown and reduced control of the airplane.

Comply with this AD within the times specified in the following, unless previously accomplished.

Obtain an initial engine oil filter sample of the affected engines within 150 hours time in service after the effective date of this AD.

Submit the engine oil filter sample within 3 days of sampling to an ISO/IEC 17025 accredited laboratory capable of performing analysis using ASTM D5185, Standard Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES).

Current Labs that comply with these requirements are as follows:

Jet Care International— United States

SPECTRO / Jet Care— United Kingdom

SPECTRO Oil AG– Switzerland

ALS Technichem PTE– Singapore

Bureau Veritas– Australia

Perform an oil filter analysis for wear metals and evaluate filter contents per the OEM approved data.

For engines that have an analysis that indicates a need for resample: perform a repeat oil filter analysis within 25 hours time in service after receiving notification from the laboratory that performed the initial analysis.

For engines that have a resample analysis that indicates a second resample : within 5 days after receiving notification from the laboratory that performed the analysis, inspect the hydraulic torque sensor immediately.

For engines that have an analysis that indicate an inspect immediately: within 5 days after receiving notification from the laboratory that performed the analysis, inspect the hydraulic torque sensor.

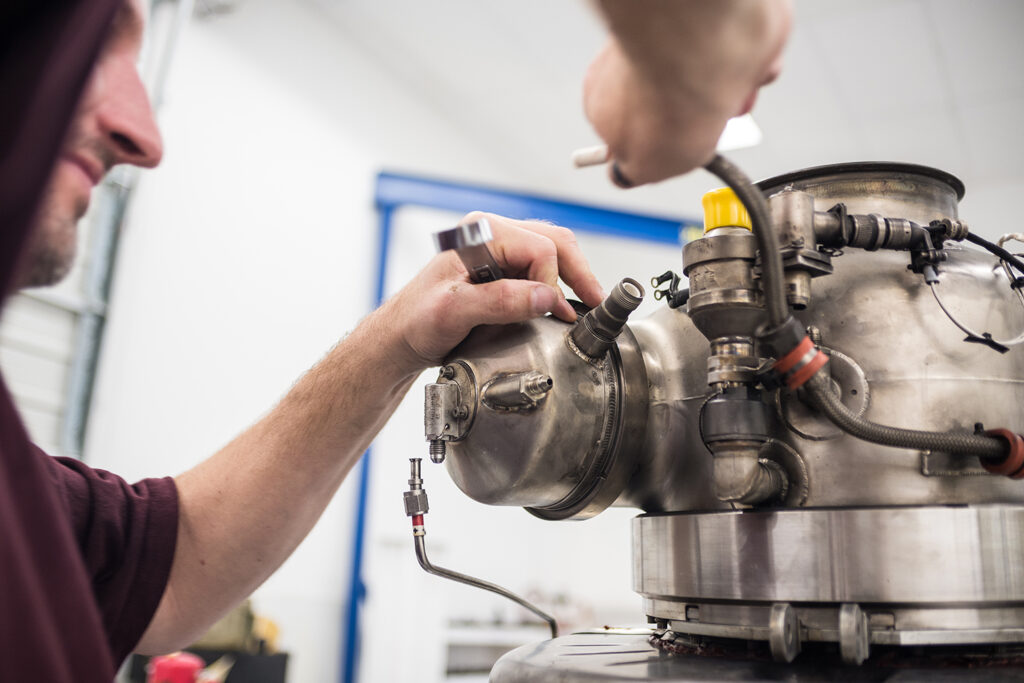

For Inspection of your Hydraulic Torque Sensor please contact your TPE331 engine shop of choice.

Important Note

After the effective date of this AD, do not use the Honeywell Torque Sensor Gear Assembly Overhaul Manual with Illustrated Parts List, 72-00-17, Revision No. 9, dated July 20, 1992, or earlier versions, to overhaul torque sensor gear assemblies, P/N’s 3101726-1, -2 or –3

The current manual revision is Rev 10.

Do you know?

Your hydraulic torque sensor is responsible for driving your Fuel Control Unit and Fuel Pump as well as Torque Indication to the cockpit?

Meet Darren Campbell

General Manager Calgary, AB

Darren Campbell began his aviation career in Thunder Bay, ON with Bearskin Airlines in 1999 as an AME apprentice. He worked for Bearskin until leaving to take an AME lead position with Kenn Borek of Calgary, AB in 2002. Darren remained with Borek until joining CD Aviation Services in 2007 as Quality Assurance Manager and Chief Mechanic for the Calgary facility. In 2012 Darren was promoted to GM / PRM for the Calgary shop. Darren is a critical team member for CD Aviation Services and contributes greatly to our success in the TPE331 market. Darren also provides TFE field service as well as APU repair for our Canadian customers. Darren enjoys camping and various outdoor sports as well as spending time with his family.

Services Offered for your TPE331

- Scheduled and Unscheduled Maintenance

- Engine Removal and Reinstallation

- LRU Trouble Shooting and Replacement

- Field Service

- Engine Evaluation

- Log Book Reviews

- Engine Overhaul CAM Inspections

- Hot Section Inspections

- Gearbox and Compressor Inspection Repair

- Vibration Analysis Prop Balance

- Borescope Inspections

- 24-Hour AOG and Technical Support

Call Us anytime 417-206-2327 www.cdaviationservices.com